K4 - welded plate heat exchanger of the "Block" type

Device description

Structure

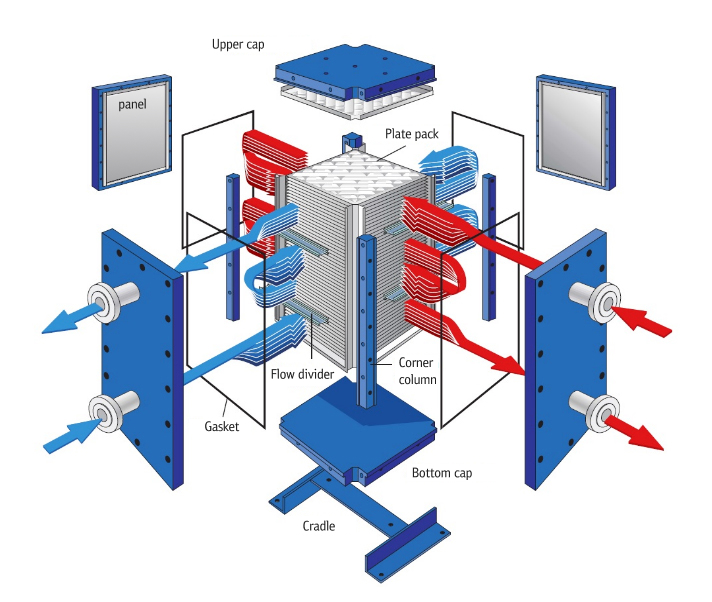

The heat exchanger consists of major componenents as follows:

- 1 - welded pack of stamped plates (meant for media heat exchange);

- 2 - upper cap (a part of an assemblable shell which is used for placing strapping tools on vertical heat exchangers);

- 3 - bottom cap (a part of an assemblable shell which is used for placing the supporting elements on vertical heat exchangers);

- 4 - panel (a part of an assemblable shell with inlet/outlet nozzles, and nozzles for blowoff and drainage);

- 5 - corner column (a part of an assemblable shell that unites caps and panels into a common vessel with a help of pins);

- 6 - panel gasket (meant for hermetic sealing of a panels pack - a panel is on each side);

- 7 - flow divider (meant for internal flow organization - paths). The quantity of paths depends on process conditions and requirements for inlets positioning;

- 8 - cradle is meant for mounting a heat exchanger to the basement..

Depending on a technological process, the heat exchanger can be vertical (footing is on a lower cap) and horizontal (footing is on an upper and bottom caps). Vertical heat exchangers are meant for heat recuperation in liquids. Horizontal ones are meant for condensation and evaporation.

Mechanical cleaning

If chemical agents can not be used in cleaning, or it's not possible or effective enough (when contaminants are large in size), it is necessary to do the manual cleaning;Mechanical cleaning can be done when panels are taken off, with water vapor or water under a pressure not exceeding 1000 bar;

The procedure of manual cleaning can be done in field, with no dismantlement, if service and safety conditions allow to do so.

All the channels of a welded plate block-type heat exchanger are seen-through that makes mechanical cleaning very effective.

The most widespread type of surface in a block-type heat exchanger is corrugated.

HESS has addiditionally developed welded plate block-type heat exchangers with unique heat exchanging surfaces which effectively solve the tasks for heat exchange when viscous and dirty media are used.

Manual cleaning of all-welded heat exchangers with a high-pressure water jet

This is why welded plate block-type heat exchangers of HESS can be an alternative to overpriced spiral heat exchangers which are, for the most part, produced abroad.

Main Features

Parameter name

Value (characteristics)

Operating temperature, ˚C

from -90 up to +500

Operating pressure, bar

up to 40

Coupling dimensions, mm

from 50 up to 1000

Maximum discharge, m3/h

1500

Plates material

Stainless steel 316, alloys 254 SMP, 904L, Hastelloy, Titanium

Material

Carbon steel, stainless steel 316, alloys 254SMO, 904L, Hastelloy, Titanium

Heat exchanging media

Water, vapor, air, gases, mixtures, oil fuel, oils, fuel acids, food grade liquids