Выполненные проекты

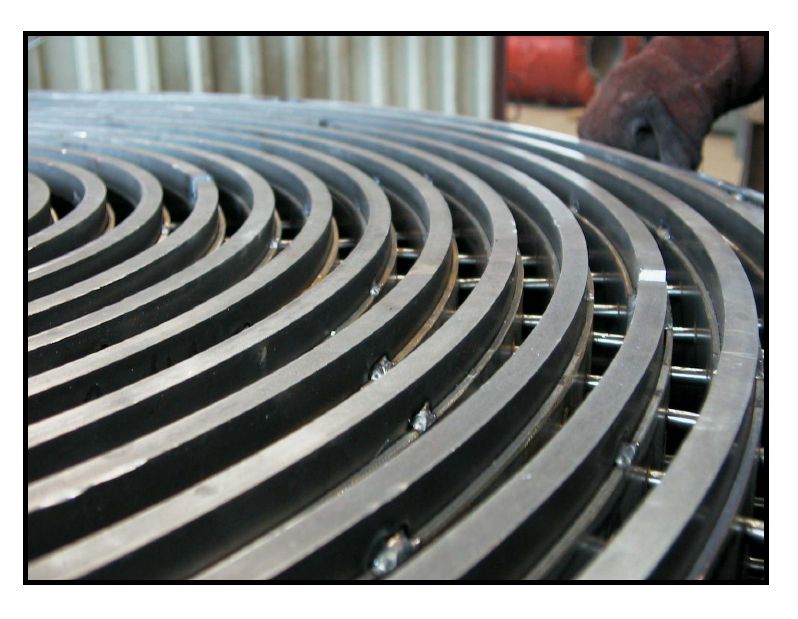

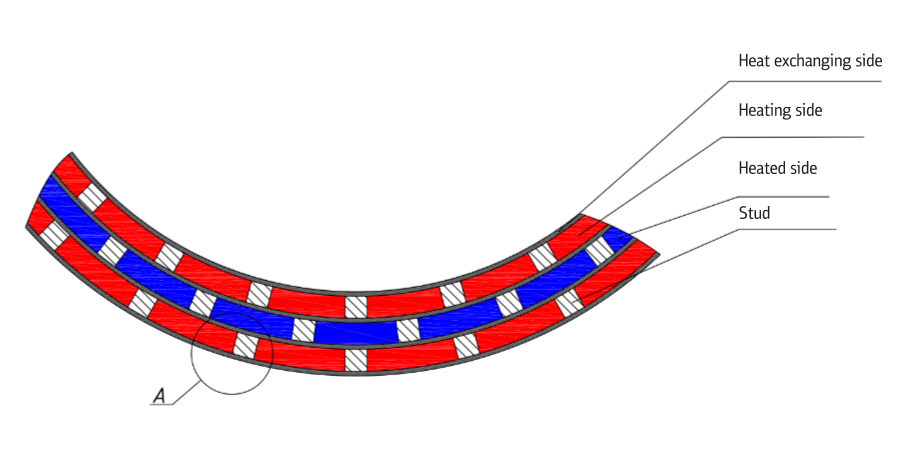

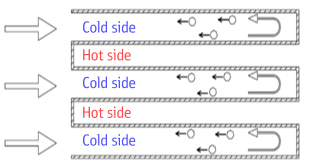

A spiral plate heat exchanger is the heat exchanger in which heating surface is formed by two metal sheets that are welded to the devision wall and rolled in the form of spirals. Spiral heat exchangers are the machines consisting of 2 or 4 channels of rectangular section that are formed by rolling 2 or 4 metal sheets as a spiral. 2-6mm-wide sheets function as heat exchanging surfaces. Inner spirals' ends are connected with a division wall, and the distance between them is fixed with studs. Spiral heat exchangers are manufactured vertical or horizontal with the 0.2-2m width spiral and 4-25mm distance between heat exchanging surfaces.

It should be mentioned that such type of surface is notable for low-scale of flow turbulence, therefore low volume-to-size ratio. At the same time, the surface of heat exchange depends on channel length and pressure drop, and the pressure drop can be limited by a customer.

But the main advantage of a spiral heat exchanger is unoccupied wide conduit. This feature allows using such heat exchangers with media containing particular matters even with particles of big size, and also with highly viscous products, non-Newtonian liquids, liquids with fibred particles. The design allows forming a channel up to 25mm width.

The heat exchange area of a spiral heat exchanger is organized in such a way that it's possible to clean it both sides but the cleaning is organized "into a dead-end", not "seen-through" like heat-blocks have. HESS has developed the hybrid solution for a heat-block - it is with studs, it has a wide channel like in a spiral heat exchanger but at the same time it can be cleaned "see-through" and is deprived of disadvantages of a spiral heat exchanger - there's no high differential but there is high coefficient of compactibility of a heat exchange surface. For more details, you can ask our specialists for a booklet with such equipment type.

Spiral heat exchangers can be used as steam condensers overhead of a column (helmet-type, with cross flow), and as flash evaporators and utilizers of flue gases.

HESS spiral heat exchangers are developed for the processes with the design pressure up to 40bar and the design temperature up to 400˚C. Flow part materials can be of any steel types and alloy (titanium, Hastelloy, SMO254, etc).

HESS spiral heat exchangers are produced on spinning machines that had been independently engineered and manufactured exactly for these purposes. HESS develops different types of spiral heat exchangers according to Customer's requests.